Technical introduction

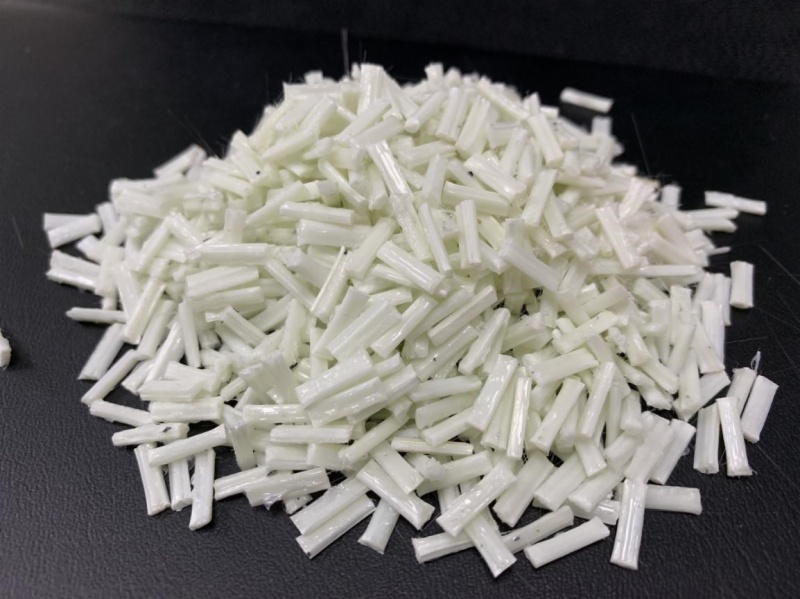

Long fiber reinforced thermoplastics referred to as "LFT", according to the different production processes can be subdivided into: LFT-G, LFT-D, etc. ;

Developed by Nanjing Quanta Chemical Equipment Co., LFT complete sets of equipment with process stability, high production efficiency and other characteristics;

The production line for PP, PA, PPA, PBT and other thermoplastic resins;

Fiber available: glass fiber, carbon fiber, basalt fiber, etc.Fiber content of 30%, 40%, 50%, 60%, to meet the needs of different users ;

Process: 1. Feeding system 2. Twin screw extruder 3. Holding frame for fiber 4. Glass fiber pre-heating system 5. Infiltration mold 6. Cooling water tank 7. Air knife 8. Strip traction machine 9. Special pelletizing Machine 10. Vibrating sieve

Practical range

Compared with the traditional glass fiber reinforced materials, LFT has the characteristics of higher elastic modulus, higher impact resistance and long service life. It is lightweight and high-performance in the fields of aviation, automobile, construction, electrical appliances and household appliances The process of change has broad prospects.

Tel: +86 13851443003

Tel: +86 13851443003  Whatsapp: +86 13851443003

Whatsapp: +86 13851443003  Email:

Email:  Address:Ningmao Road,Guozhuang,

Address:Ningmao Road,Guozhuang,